Description

- Description

- Features and Benefits

- Specs

- Labels and SDS Forms

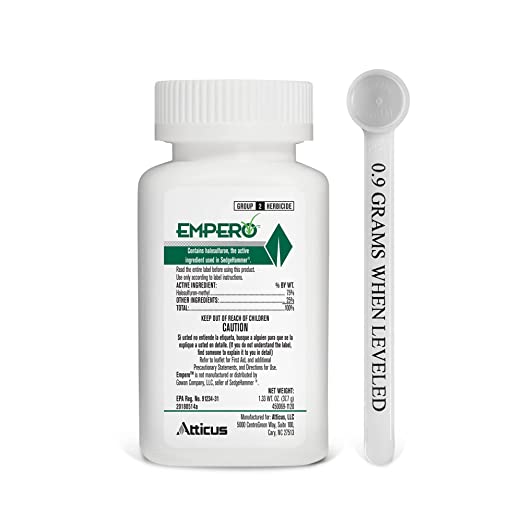

Empero is an excellent post-emergent herbicide that immediately controls unwanted weeds and turfgrass. It is commonly used on golf courses, residential properties, commercial and residential turfs, and recreation areas. Provides a fast-acting, gentle solution by inhibiting the growth of nutsedges and broadleaf weeds without leaving damaging effects. Better results occur within 7 to 14 days, depending on size and species. This selective herbicide is formulated as a water dispersible granule that easily dissolves and may be used for spot treatment. It has superior control of nutsedge, as well as horsetail and other stubborn broadleaves. Perfect for cool and warm season turfgrass and it is rainfast within four hours. It is proven to be safe to people and pets once it dries. Best alternative to SedgeHammer ProSedge. Comes in 1.33 oz. bottle with a measuring spoon.

DIRECTION FOR USE

It is a violation of Federal law to use this product in any manner inconsistent with its labeling. This product can only be used in accordance with the Directions for Use on this label or in separately published Atticus, LLC Supplemental Labeling.

Do not apply this product in a way that will contact workers or other persons, either directly or through drift. Only protected handlers may be in the area during application. For any requirements specific to your State or Tribe, consult the agency responsible for pesticide regulation.

Mixing Instructions

EMPERO is a water dispersible granule designed to be diluted with water at the rates listed in the specific crop use directions. Fill the spray tank with approximately ½ of the desired volume with water or carrier. With the agitation operating, add the specified amount of the formulation as listed in the targeted crop use directions. Complete the filling process while maintaining agitation. Remove the hose from the mixing tank immediately after filling to avoid siphoning back into the carrier source. Add nonionic surfactant and other spray additives as the last ingredients in the tank. Allow time to fully disperse.

Since this product forms a suspension in water, it is important to maintain good agitation during mixing and spraying. If the spray suspension is allowed to settle for a short period of time, be sure to agitate the spray suspension for a minimum of 10 minutes. Apply spray solutions within 24 hours after mixing.

Mix 0.03 ounces (0.9 gram) of this product (using the measuring scoop provided) in 1 - 2 gallons of water to treat 1,000 sq. ft. Add 2 teaspoons (1/3 fluid ounce) of nonionic surfactant per gallon of water. Measured this product as a level and not a rounded scoop. Mix or shake thoroughly for at least two minutes to completely disperse this product. To ensure that this product remains thoroughly mixed while spraying, occasionally shakes the spray suspension.

Spray Additives

Spray additives such as the nonionic surfactant (NIS) are used with EMPERO to improve performance. The typical nonionic surfactant contains a minimum of 80% NIS and is accepted by the EPA for use on food crops. The use rate is 0.25 to 0.5% NIS concentrate (1 to 2 quarts per 100 gallons of spray mixture). Always use NIS in the spray mixture.

For specific details, consult the use site directions

Application Methods

Apply this product by ground to produce uniform coverage on growing weeds or soil to achieve consistent weed control.

Uniform, thorough spray coverage is important to achieve consistent weed control. Calibrate application equipment according to manufacturer’s specifications. Use nozzle type arrangements that provide optimum spray distribution and maximum coverage while avoiding contact with sensitive crop foliage.

Thoroughly clean application equipment immediately after use and prior to spraying a crop other than corn or grain sorghum. See Spray Equipment Cleanout section of this label for complete details.

Ground Applications

When EMPERO is applied by ground equipment, use in a minimum of 10 gallons of water per acre for a broadcast application. In dense weed populations and thick canopy cover, higher spray volumes are necessary, e.g. 15 – 20 gallons of water per acre. Use the proper spray volume and nozzles that will ensure thorough and uniform coverage of the targeted weeds. Use directed applications to avoid contacting sensitive crop foliage. Select nozzles that will provide optimum spray volume, distribution, and coverage at a pressure (psi) that minimizes spray drift. Inspect nozzle distribution during application to avoid streaking and overspray.

Spray Drift Management

Do not allow this product to drift onto neighboring crops or non-crop area or use in a manner or at a time other than in accordance with label directions because animal, plant or crop injury, illegal residues or other undesirable results may occur.

AVOIDING SPRAY DRIFT AT THE APPLICATION SITE IS THE RESPONSIBILITY OF THE APPLICATOR. The interaction of many equipments – and weather-related factors determine the potential for spray drift. The applicator and the grower are responsible for considering all these factors when making decisions. Where states have more stringent regulations, they must be observed.

Sensitive areas:

Use pesticide products adjacent to sensitive areas only when there is minimal potential for drift or off-target movement, e.g. wind is blowing away from non-target crops, residential areas, known habits for threatened or endangered species, etc.

In California (only), particularly sensitive crops are identified as cotton and prunes. In applications near these sensitive crops utilize the following buffer zones:

- A ground application shall not be made closer than 1 mile from sensitive crops unless wind direction during the application is away from sensitive crops. When wind direction during the ground application is away from sensitive crops, the ground application shall not be made closer than 0.5 miles from sensitive crops.

Spray Equipment Cleanout

The mix tank and spray equipment cleanout is an important stewardship activity to avoid injury to desirable crops. It is important to clean all mixing and spraying equipment immediately after use and before using pesticide products including EMPERO. This is especially important prior to spray a crop other than grain sorghum and corn.

To clean the spraying equipment, follow the procedure outlined below:

- Completely drain the mix tank and/or sprayer, and then wash thoroughly the tank, sprayer, boom, and nozzles with clean water. Drain the system again.

- Fill the mixing or spray tank half full with clean water and add domestic ammonium, normally a 3% solution, at a dilution rate of 1% vol/vol ammonium or 1 gallon per 100 gallons of rinsate.

- Completely fill the tank(s) with additional clean water. Agitate and recirculate and flush out the boom and hoses. Let the system run for 10 – 15 minutes. Drain the system completely.

- Remove nozzles and screens and dislodge any visible solid material. Then soak them in a 1% vol/vol ammonium solution. Inspect the nozzles and screen and remove any visual residues.

- Repeat the above procedure for the second time.

- Flush the mix tank and/or sprayer, boom, and hoses with clean water. Drain the system again and inspect for any visible residues. If present, repeat the cleaning cycle again.

- If the rinsate cannot be disposed of by use according to label instructions, contact your State Pesticide or Environmental Control Agency, or the Hazardous Waste representative at the nearest EPA Regional Office for guidance.

Tank Mixtures

To improve this product’s effectiveness, apply in combination with other pesticide products that are registered for the same crop and application techniques. A list of potential herbicide tank mixture partners is provided in the use direction section under each crop. This list is an example of products used but is not an all-inclusive list. For current information on the best tank mixture partner in your area, consult with the local dealer, distributor or State Agricultural Extension service.

It is the pesticide user’s responsibility to ensure that all products in the listed mixtures are registered for the intended use. Users must follow the most restrictive directions for use and precautionary statements of each product in the tank mixture.

If EMPERO is to be tank mixed with other herbicides, conduct a compatibility test prior to mixing. Use a small container and mix all components in a small amount, usually 0.5 to 1qt. of spray. Combine all products in the same ratio and order of addition as in the proposed spray mixture. Observe the mixture for indication of incompatibility which usually occurs in 10 to 30 minutes after mixing. If incompatibility is observed, try changing the order of addition of the components. The guideline on tank mixture partners is driven by formulation type. Start with wettable powders (WP’s) including water-soluble bags (WSB’s), water dispersible granules (WDG’s), suspension concentrated (SC’s) or flowable (F’s), all with very good agitation. Next, follow with water miscible concentrates and emulsifiable concentrates (EC’s) before adding drift control additives, nonionic surfactants (NIS’s) or crop oil concentrate (COC’s). After vigorous agitation, there must be a homogeneous suspension. Let the final tank mixture stand and observe for any rapid settling or floating of components. If any indications of physical incompatibility develop, do not use this mixture for spraying.

For Best Performance

Many factors such as application rate, weed species, weed pressure, conditions of weeds including size and climatic conditions impact the degree of weed control. Applications made to actively growing weeds at the early stages of development as described below will optimize performance. In post-emergent weed applications, early treatment is best to control the weeds vying (competing) with the crop. For residual control from early post-emergent treatments, a second application may be needed to control later germination of weeds.

EMPERO is quick to act on targeted weeds by stunting growth allowing the crop to overtake the development of the targeted weeds. Once the development of the targeted weeds is stunted, the leaves and growing point begin to discolor and die. Complete control typically occurs within 7 to 14 days depending on the weed size, species, and growing conditions. Depending on the stage and development of the targeted weeds, control generally takes place in 7 to 14 days.

Empero is an excellent post-emergent herbicide that immediately controls unwanted weeds and turfgrass. It is commonly used on golf courses, residential properties, commercial and residential turfs, and recreation areas. Provides a fast-acting, gentle solution by inhibiting the growth of nutsedges and broadleaf weeds without leaving damaging effects. Better results occur within 7 to 14 days, depending on size and species. This selective herbicide is formulated as a water dispersible granule that easily dissolves and may be used for spot treatment. It has superior control of nutsedge, as well as horsetail and other stubborn broadleaves. Perfect for cool and warm season turfgrass and it is rainfast within four hours. It is proven to be safe to people and pets once it dries. Best alternative to SedgeHammer ProSedge. Comes in 1.33 oz. bottle with a measuring spoon.

| ACTIVE INGREDIENT | Halosulfuron - methyl 75% |

| TARGET PESTS | Cocklebur, horsetail, redroot pigweed, smooth pigweed, common ragweed, giant ragweed, sunflower, velvetleaf, kyllinga, purple nutsedge, and yellow nutsedge. |

| FOR USE IN | Cool and warm season turfgrass, commercial and residential turf, golf course, public recreation area, residential property, and right-of-way. |

| MANUFACTURER | Atticus |

| EPA REGISTRATION | 91234-31 |

| NOT FOR SALE TO | AZ, ME, MT, ND, WY |

| COMPARABLE PRODUCTS | Sedgehammer, Sedgehammer Plus, Prosedge, Sedgemaster |

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.